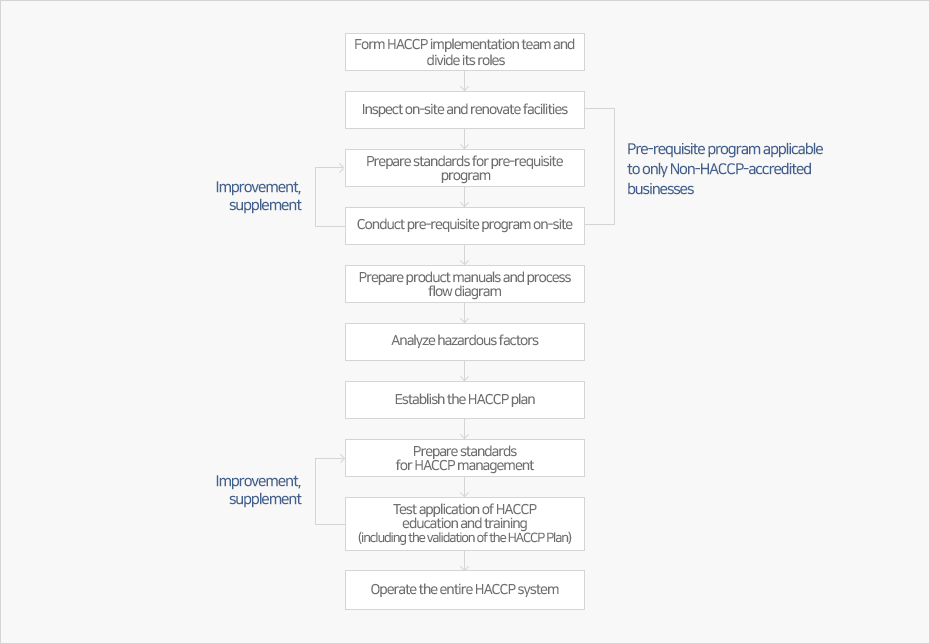

Application procedures

The procedures for implementing HAACP in food manufacturing and processing facilities and mass catering services is as follows:

Form HACCP implementation team and divide its roles

Forming the HACCP team in charge of establishing and operating the HACCP system

Including professional staff in various fields, such as quality control, production, official business and research and development with the leader and team member sharing specific and practical roles

Inspect on-site and renovate facilities

Inspecting the basic sanitary management facilities for safe food and the status of management

Improving safety issue in establishing and operating the basic CMP and SSOP

Prepare standards for pre-requisite program and conduct pre-requisite program on site

Preparing a pre-requisite program standard including business establishment, sanitary management, manufacturing facilities, refrigerating and freezing facilities, water, storage/transportation, inspection and recall program

Identifying practical issues and solutions and revising the standard after on-site inspection

Prepare product manuals and process flow diagram

Preparing product manuals explaining ingredients in products, specification, expiration date and usage

Preparing the process chart of manufacturing/processing/cooking, schematic diagram of air conditioning system and water and wastewater treatment The materials above can be used as the primary date for analyzing hazards

Analyze hazardous factors and prepare the HACCP plan

Conducting risk assessment on possible hazards by ingredients and manufacturing processes

Establishing the HACCP plan including critical control points, critical limits, monitoring method, improvement method for non-compliance with standards

Prepare standards for HACCP management

Preparing the HACCP management standard including HACCP team formation, product manuals, process flow diagram, hazard analysis, critical control point, critical limit, monitoring method, corrective action, verification, education and training and documentation and recording

Test application of HACCP education and training

Test application of HACCP plan after education and training for field staff, managers, HACCP team members

Checking whether the plan is effectively implemented and operated in actual practice by implementing the validation of the HACCP plan

Entire operation of HACCP system

Full operation of HACCP system through the improvement on problems in the HACCP plan by reflecting the results of the validation of the program and application for certification of HACCP-applied business establishment to the branch offices of the Ministry of Food and Drug Safety